QUALITY SERVICES BASED ON

COMPREHENSIVE MANAGEMENT

SERVICES TO INDUSTRY BASED ON

LEAN MANAGEMENT

PRECISION MACHINING AND TURNING

40 YEARS EXPERIENCE IN THE DESIGN AND MANUFACTURE OF HIGH PRECISION PRODUCTS

Special parts for advanced industrial and technological sectors

Continuous investment in advanced technology. Reliability and innovation

Work philosophy oriented to solve our clients' challenges

QUALITY AND MANUFACTURING CAPACITY

Materials. Stainless and carbon steels, aluminum, titanium, copper alloys, brass, bronze and technical plastics.

Technology. 24 CNC lathes 7x and 12x, fixed and movable headstocks. 4X CNC horizontal center.

Precision. Tolerances +/- 0.01 and complex geometries.

Finishing. Automatic cleaning station by immersion and agitation, Roughing station by sliding. Ultrasonic cleaning.

INDUSTRIAL ORGANIZATION AND MANAGEMENT

Lean Factor, a proprietary management system applied to production processes to improve the efficiency and quality of our customers' products.

Total Quality Factor, a management system that allows us to control the entire process, from product definition to delivery logistics.

Logistics and Customer Service, an integral team in the management of deliveries and solution of incidents.

KEY PROJECTS

BEVEL GEARBOX

Description

Gear teeth in 42 CrMo4 steel Ø45x40 mm.

Internal thread pitch 18, machined twice to meet the width of 9 with special sharpened tool with radius:0.2, requiring a Ra:1.6.

Tolerances: 0.01.

Value Chain

Production Engineering.

Prototypes and Series Industrialization.

NEEDLE FOR EYE SURGERY

Description

Titanium and stainless steel Ø 0.1mm drills for depths up to 50 times the diameter.

Concentricity: 0.001mm.

Value Chain

Production Engineering.

Prototypes and Series Industrialization.

TAP TRAWL

Description

Dimensions: Ø70x110 mm.

Transversal drilling and milling in 303 stainless steel with internal grooving and off-center threading.

Ra: 0,8.

→ Finished machine part without burrs in the hole communication.

Value Chain

Design.

Production Engineering.

Prototypes and Series Industrialization.

CONNECTOR

Description

Dimensions: Ø19x40 mm. Material: Stainless steel 304.

Laser marking / Ra: 0,4.

Finished machine part with no burrs in the hole communication of the operating and counter-operating bores.

Value Chain

Production Engineering.

Prototypes and Series Industrialization.

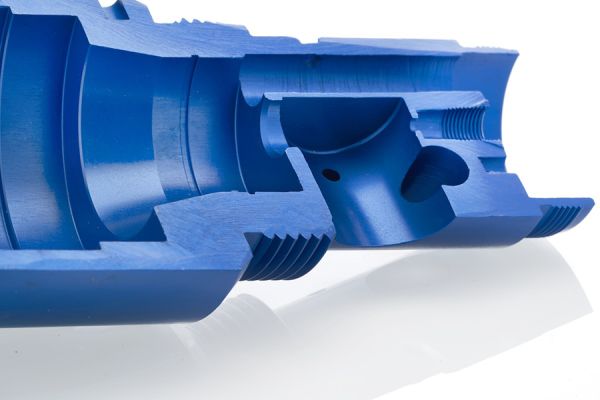

DEFENSE

Description

Dimensions: Ø70x140 mm. Material: aluminum

Surface treatment: anodized

Production process:

8-axis "multitasking" automatic CNC lathe with 2 towers and 2 heads.

Transversal, inclined and frontal motorized operations.

Space challenge for mounting 34 tools. Recurrence to triple drill holders, double square holders and triple transverse motorized transverse. In addition, use of bi-diametric drills and milling cutters without pre-drilling.

Off-center tapped and milled off-center drills.

Ra 0.8 micron finish.

Deep holes with flat bottom, with tolerances of 3 hundredths, requiring high chip evacuation with milling cutter.

Finished machine part without burrs in the hole communication.

Value Chain

Production Engineering.

Prototypes and Series Industrialization.

HARDENED LATCH

Description

Dimensions: Ø54x18 mm. Material: 16MnCr5

Production process:

Transverse copy milling operations with Ø8 ball end mill under CAM programming.

Shape tolerances on this surface of 0.05; roughness requirement of Rz 6.3 and radius tolerance of ±0.02.

Off-center bi-meter hole with H9 tolerance reamed with concentricity tolerance of 0.05.

Value Chain

Production Engineering.

Prototypes and Series Industrialization.

CONTACT WITH US

If you are interested in our solutions or would like more specific information to know our adaptability to your needs.