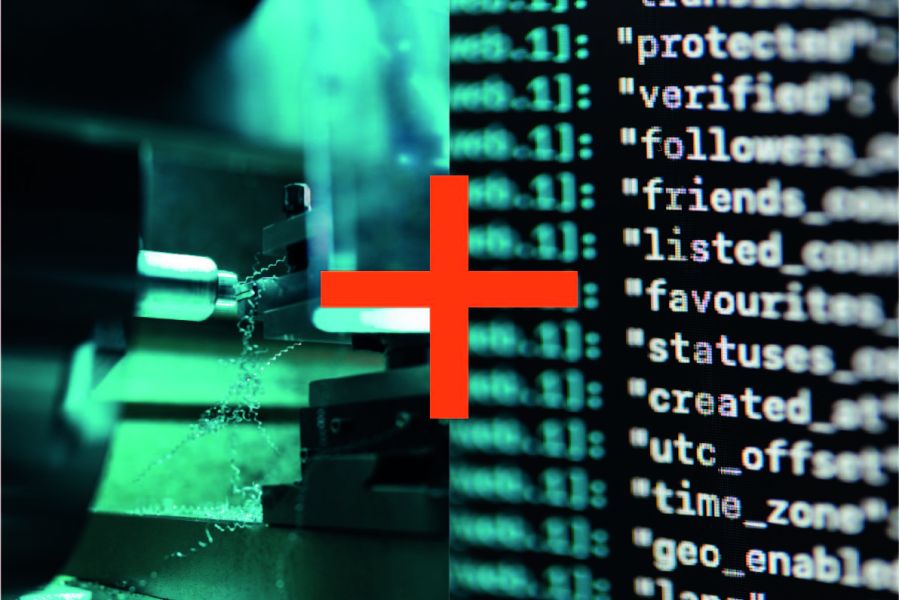

Factor increases the competitiveness of its customers with Nakamura JX-250

It continues to focus on the most reliable, productive and flexible equipment, in order to offer the most advanced and innovative option in the market

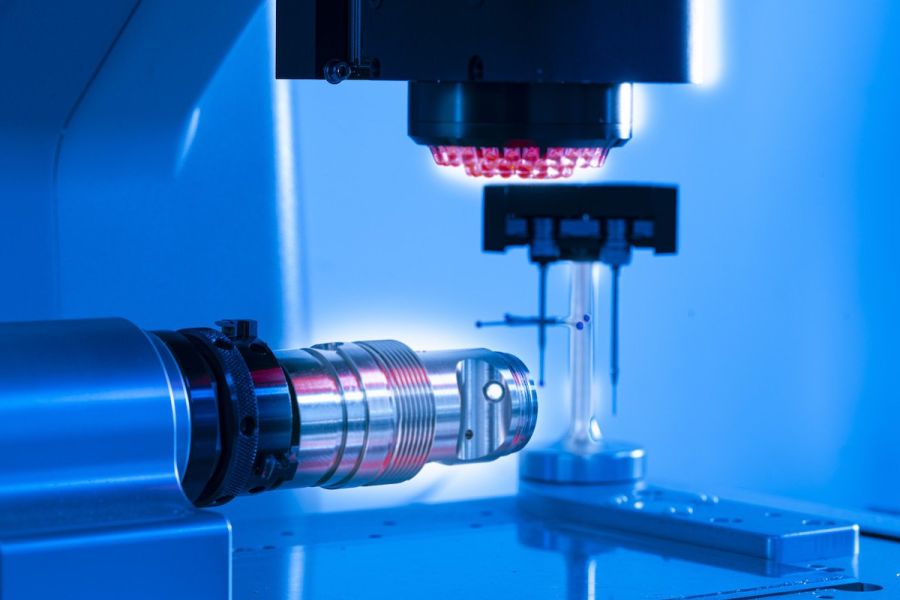

One of Factor's main purposes is to increase the competitiveness of its customers, as well as to consolidate its position in the manufacture of products with high added value, complexity of operations, precision and greater dimensional range. And with both objectives in focus, it has acquired the Nakamura JX-250 high-end multi-tasking lathe, which will considerably expand the industrial capacity for the manufacture of parts.

The machine's top unit, which features an automatic tool changer, offers exceptional performance, and its 18,000-rpm milling head is the smallest on the market, ideal for some highly complex jobs.

The head has a magazine for 80 tools and each turret is equipped with a 12-position Y-axis. Thus, this machine has up to 104 tools, giving it the necessary flexibility for highly complex jobs. At the same time, it offers enormous productivity, as it can work with up to three tools at the same time. “We are talking about a machine that combines the features of a high-performance, high-productivity multitasking automatic lathe with the milling capacity of a machining center,” says Factor.

The JX-250 has twin spindles opposite each other, which makes it possible to finish parts in two setups or produce large-format shafts, since the maximum turning diameter is 320 millimeters and it reaches a turning length of 1,650 millimeters. The equipment also incorporates the function of gear hobbing, both internal and external.

This lathe has the “HAN-BEI Milling Machine”, equipped with a probe, and an in-process part measuring system. And, in addition, it has the second-generation 3D Smart Pro AI Software, which features Artificial Intelligence and has the great advantage of allowing 3D models to be imported directly and input into the Smart X. In fact, it is the world's most advanced and innovative software in its category.

Ultimately, the Nakamura JX-250 will offer a number of benefits to Factor's customers. First, it will expand production capacity. On the other hand, it will increase the dimensional range of the product and increase its complexity due to the number of tools available on the equipment. It will also boost competitiveness, since it combines the high productivity of an automatic twin-turret lathe with the high performance of a machining center, allowing greater complexity by number of operations on a single piece of equipment. And, in terms of quality, the device is equipped with measuring rulers on all its axes for maximum working accuracy, and a measuring probe, which allows the measurement of workpieces in process.

Thus, Factor reinforces, once again, its commitment to cutting-edge technology with this multitasking lathe model, the first in Spain capable of working with three tools simultaneously. One more example that it has the most reliable, productive and flexible equipment to offer its customers the most competitive option in the market.