Factor is I4Q project partner

Industrial Data Services for Quality Control in Smart Manufacturing (i4Q) will help European SMEs overcome the obstacles preventing them from entering the Fourth Industrial Revolution.

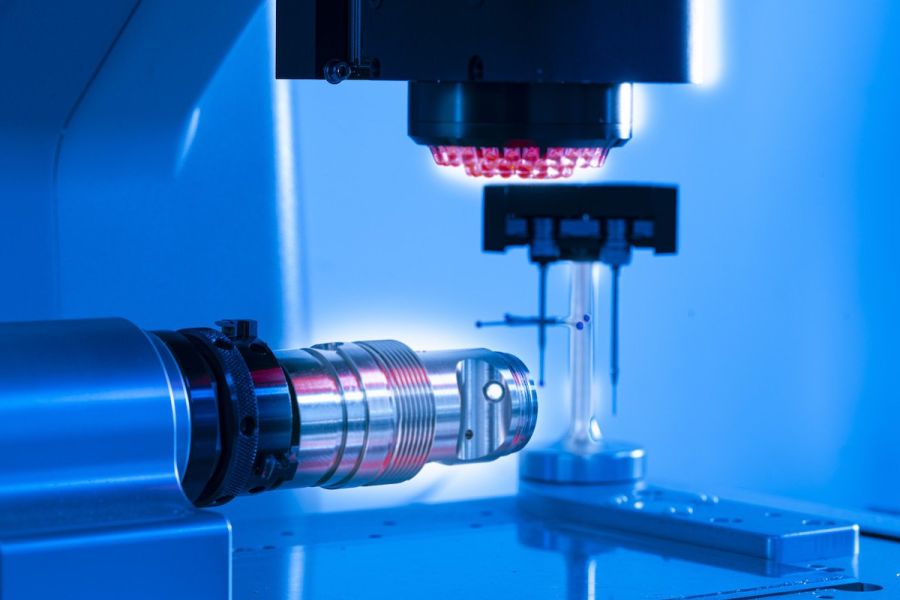

The project will provide a complete solution to improve the quality of manufactured products with the goal of defect-free manufacturing, thus driving the concept of a fully digitized smart factory.

The i4Q project kicked off in 2020, being now in its last stage, where it will provide a complete suite of 22 IoT-based i4Q Solutions, capable of managing the huge amount of industrial data coming from factory devices and thus improving productivity comprehensively at low cost.

I4Q is formed by a team of 25 partners with the common goal of manufacturing with ZERO DEFECTS. We continuously face the challenge of redesigning and adjusting our manufacturing systems, adapting our processes to produce products that adapt to specific customer requirements and guaranteeing high quality under permanent constraints related to:

Reducing production costs

Reducing waste, scrap and defects

Reducing production costs and lead times.

All this under a scenario based on environmental sustainability, the need to minimize our carbon footprint and energy efficiency.

We are proud to be part of this team. Factor is one of the pilot plants that has established functional and operational requirements for the systems under development. We have provided, thanks to our MES and MTLink (Fanuk) systems, real process, machine and planning data to be used in the algorithms of the suite, and we will soon test the i4Q Beta solutions in our facilities to refine the results obtained.

Thanks to all I4Q partners for the great effort to reach the great expectations we have in 2023!

Here is a LINK TO THE PROJECT WEBSITE.