Factor transforms CNC precision machining with i4Q Solutions

By adopting i4Q, the company has improved the operational efficiency and positioned itself as a leader in data innovation

Factor, a leader in high-precision parts manufacturing, has successfully implemented i4Q solutions, ushering in a new era of data-driven decision-making and enhanced operational efficiency.

The i4Q project has served as a catalyst for Factor's digital transformation, empowering the company to optimize its CNC precision machining processes and drive innovation in the Industry 4.0 landscape.

Key Outcomes of i4Q Implementation

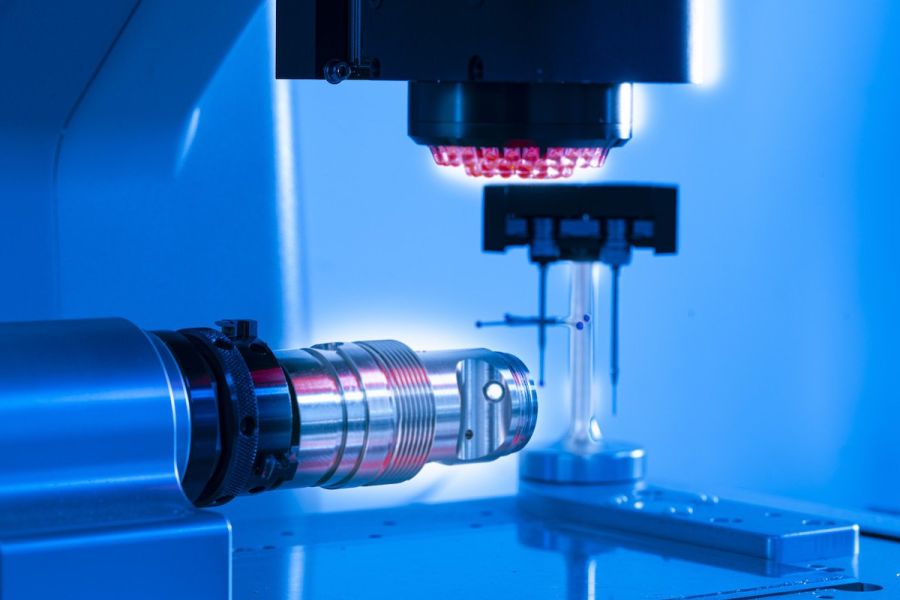

The implementation of i4Q has enabled the transformation of CNC precision machining, yielding a series of key results.

- Dedicated Digital Processes Team: i4Q has empowered Factor to assemble a dedicated team of experts specializing in infrastructure management, data analytics, and organizational strategy. This team ensures that Factor remains at the forefront of technological advancements and leverages data-driven insights for continuous improvement.

- Value-Driven Projects for Improved OEE: i4Q has fueled a series of high-impact projects aimed at enhancing Overall Equipment Effectiveness (OEE) across Factor's manufacturing operations:

- AutoCalidad: High-precision, real-time data acquisition and measurement for improved quality control and process qualification.

- Tool Life Improvement: Optimization of tool life and reduction of downtime through data correlation and analysis.

- Energy Optimizer: Significant energy consumption reduction through intelligent monitoring and optimization.

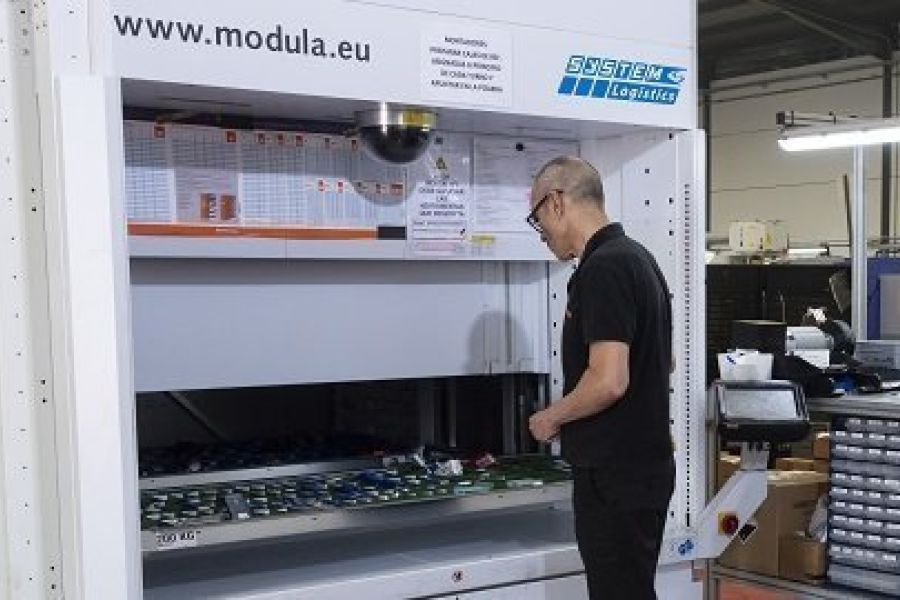

- Data Repository: Centralized data storage from diverse sources, ensuring long-term data availability for advanced analytics and decision-making.

- Enhanced Infrastructure: i4Q has provided a roadmap for infrastructure enhancements, including the implementation of Internet of Things (IoT) sensors, exploration of advanced industrial data communication protocols, and robust data cleansing and storage practices. This modernized infrastructure forms a solid foundation for Factor's data-driven future.

i4Q's Impact on Factor's CNC Precision Machining

The impact of i4Q on CNC precision machining has been reflected in:

- High-Quality Data as a Strategic Asset: i4Q has emphasized the critical importance of high-quality data for effective decision-making in the context of complex, high-demanding machining processes.

- Data-Driven Decision-Making: Factor now leverages i4Q tools and functionalities to gather, analyze, and visualize data, enabling data-driven decisions that optimize production processes and ensure high precision.

- Enhanced Quality and Efficiency: Specific i4Q solutions directly address Factor's core needs by improving quality control, reducing downtime, and optimizing production efficiency.

- Scalability and Future-Proofing: i4Q offers scalable solutions that can grow with Factor's evolving needs, positioning the company for continued success in the dynamic Industry 4.0 landscape.

"Factor's experience with i4Q exemplifies the transformative potential of Industry 4.0 solutions for companies engaged in CNC precision machining and high-demanding manufacturing processes. By embracing i4Q, Factor has not only enhanced its operational efficiency but also positioned itself as a leader in data-driven innovation", highlights Alfredo Giménez Millán, Factor's Innovation Director.