New CMM added to Factor's machinery park

Hexagon Metrology's Global Lite and PC-DMIS CAD software, based on the Manufacturing Intelligence Enhanced Productivity concept, is becoming the fundamental quality tool for automating and optimizing the company's inspection and control processes.

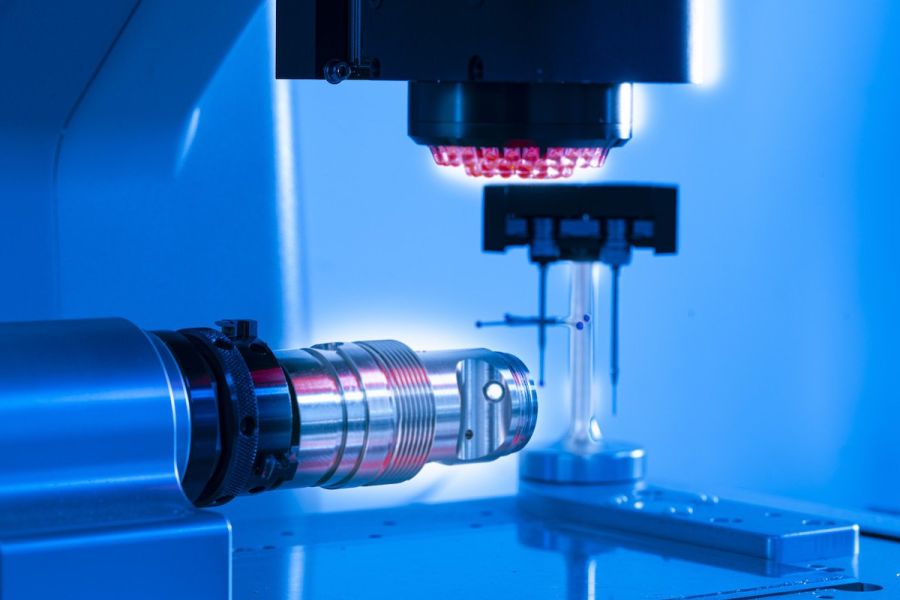

In an ongoing effort to maintain high quality standards and gain operational efficiencies, we are pleased to announce the addition of a new coordinate measuring machine (CMM) to our machine fleet.

The Global Lite will allow us to make accurate and reliable measurements to ensure the quality of our products. The combination of the Global Lite CMM and PC-DMIS CAD software provides us with a complete solution from data acquisition to analysis and reporting. This allows us to get faster and more accurate results, optimizing our resources and reducing production time.

The Global Lite 7.7.5 CMM offers reliable and accurate three-dimensional inspections with a maximum resolution of 0.1 μm and a high-resolution scale of 0.039 μm, while improving the efficiency of inspection processes thanks to the possibility of automating them and running them in batches. On the other hand, its XYZ measurement range (700 - 500 mm) is 100% adapted to the type of parts and assemblies we develop at Factor.

In addition, the Manufacturing Intelligence Enhanced Productivity approach gives us a comprehensive view of our processes, helping us to identify opportunities for improvement and optimization in real time. The machine and its control software are now fully operational in our facilities, helping us to gain a deeper understanding of our measurement data so that we can make informed decisions to optimize our manufacturing processes and deliver significant improvements to our customers.