Factor advances in precision metrology with the VIMAX project

An initiative in collaboration with ai2 (UPV), photonicSENS, and AGFRA

At Factor, we continue to advance in the development of innovative solutions for industry. Our participation in the VIMAX project is a clear example of our commitment to continuous improvement and technology applied to quality control.

The project, developed in conjunction with the Institute of Industrial Automation and Computer Science (ai2) at the Polytechnic University of Valencia (UPV), the technology company Photonic Sensors & Algorithms S.L. (photonicSENS), and the engineering firm AGFRA, aims to create a high-precision online metrology device capable of measuring parts in real time with micron accuracy.

A milestone in industrial metrology

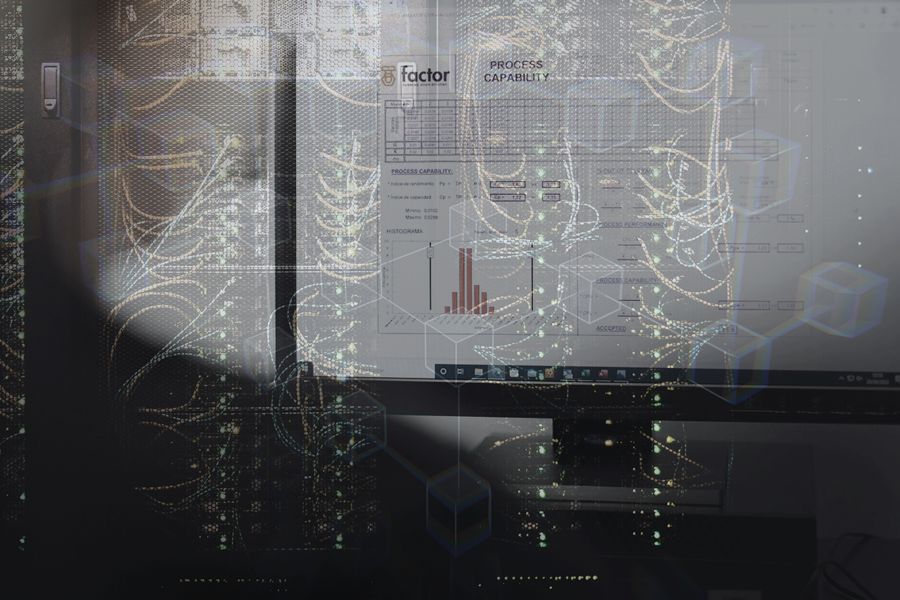

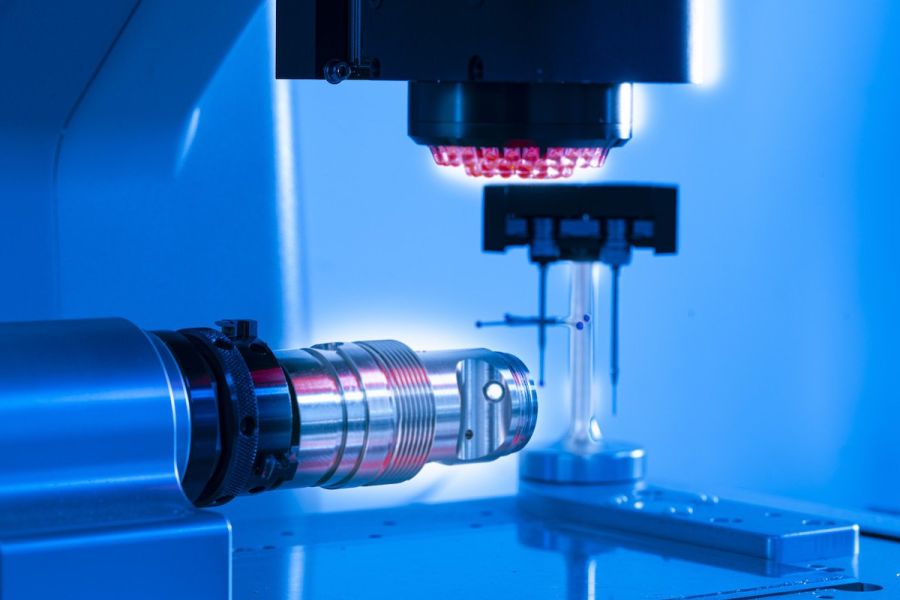

VIMAX is tackling a major technological challenge: developing a low-cost online metrology system that can inspect 100% of manufactured parts at the same speed at which they are produced. To achieve this, the consortium is working on a technology based on artificial vision cameras capable of achieving micron-level precision and processing 30 images per second.

The result will be an autonomous measuring station that can analyze both the exterior and interior of parts without the need to cut them, a breakthrough that will transform quality control processes in the manufacturing industry.

Collaboration and knowledge sharing

Each entity participating in the project contributes specialized and complementary knowledge that is essential to its success.

- photonicSENS contributes its pioneering technology in 3D cameras, the basis of the measurement system, as well as its experience in the development, assembly, and layout of these devices to ensure maximum precision.

- AGFRA contributes its expertise in engineering and industrial automation, which is key to the design and manufacture of the prototype, ensuring its robustness and adaptability to different production environments.

- The ai2 Institute (UPV) contributes its extensive knowledge of robotics, computer vision, and advanced algorithms, which are essential for 3D image reconstruction and programming the high-precision mobile prototype.

- As the project leader, Factor coordinates the initiative and contributes more than 40 years of experience in precision manufacturing. In addition, we provide the consortium with the infrastructure and production lines necessary to validate the system in a real industrial environment.

Current status and next steps

The system has already demonstrated its ability to measure with micron precision in the laboratory. The project is currently in the development phase of the robotic mechanical system. The next steps will focus on adjusting the automatic system and defining the mechanism for securing parts for accurate measurement.

Subsequently, the VIMAX prototype will be validated in a pilot scenario that simulates a real industrial environment, with continuous flow and error handling tests.

Expected impact on the industry

The implementation of the VIMAX system will represent a qualitative leap for industrial metrology. Its accessible design will allow the manufacturing industry, especially SMEs, to incorporate high-precision inspection technology at an affordable cost.

The expected benefits include improved quality and efficiency, by inspecting 100% of parts and reducing the defect rate by up to 90%; cost reduction, thanks to shorter verification times and less waste of raw materials; and increased competitiveness by ensuring more demanding quality standards.

Collaboration and open innovation

Participating in consortiums such as VIMAX allows us to tackle technological challenges that would not be possible individually, promoting knowledge transfer between academia and industry. For Factor, these types of collaborations -as in the European projects i4Q, TALON, and SUN- consolidate our position at the forefront of innovation and strengthen our commitment to Industry 4.0.

Combining the experience of senior profiles with the energy and new perspectives of young talent is another pillar of the project. Experienced engineers and innovation technicians collaborate in a dynamic environment that promotes creativity, mutual learning, and agile problem solving.

Talent and shared learning

The development of VIMAX is also proving to be a space for learning and collaboration between different profiles and generations. The union between university research, the agility of a technology company, and Factor's industrial experience generates a unique synergy, where innovation translates into practical solutions applicable to the real market.

In this context, combining the experience of senior profiles with the energy and fresh perspectives of young talent is proving particularly enriching. Experienced engineers, engineering and quality managers guide and collaborate with younger innovation technicians in a dynamic environment that encourages mutual learning and creative problem solving.

Junior profiles, for their part, play an active role in the development of the project: they participate in monitoring progress, conducting tests, and evaluating results. For them, VIMAX represents an exceptional opportunity to train in cutting-edge technologies and develop their careers in emerging areas such as Industry 4.0, robotics, and artificial intelligence.

Towards a new era of industrial quality control

With enthusiasm and perseverance, the Factor Ingeniería team is moving towards achieving the technical objectives of the VIMAX project. The collaboration with ai2 (UPV), photonicSENS, and AGFRA is laying the foundations for a new generation of more accurate, efficient, and accessible industrial metrology systems.

VIMAX represents another step forward in the technological evolution of the sector and in Factor's commitment to innovation applied to the improvement of production processes and the development of the industry of the future