Factor, the first European site to launch the final validation phase of the SUN project

Pioneering tests in a real industrial environment to promote safety through Extended Reality

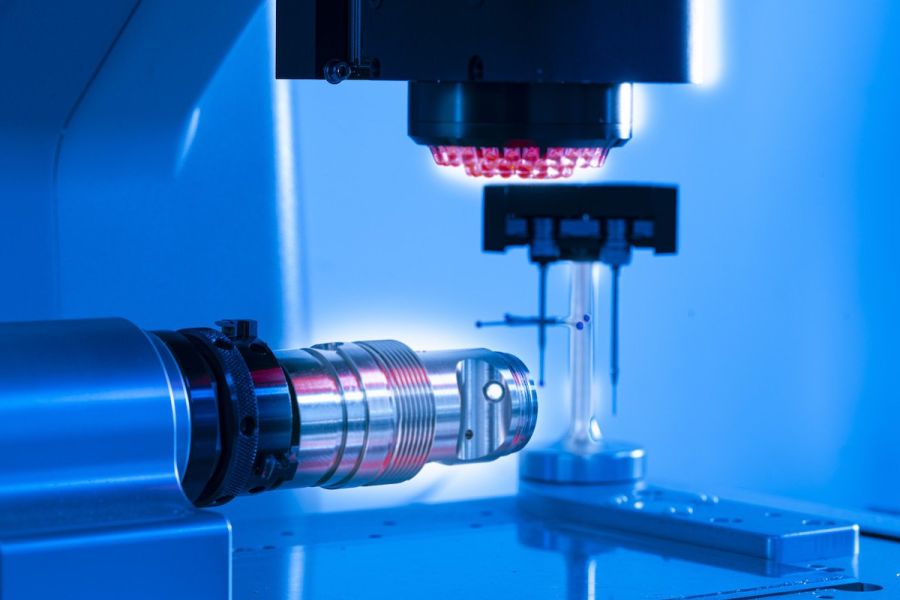

At Factor, we continue to advance our commitment to innovation applied to industry by participating in the European SUN project, an initiative that develops an integrated Extended Reality (XR) platform to improve safety, occupational health, and interaction in professional environments.

A leading industrial pilot project in Europe

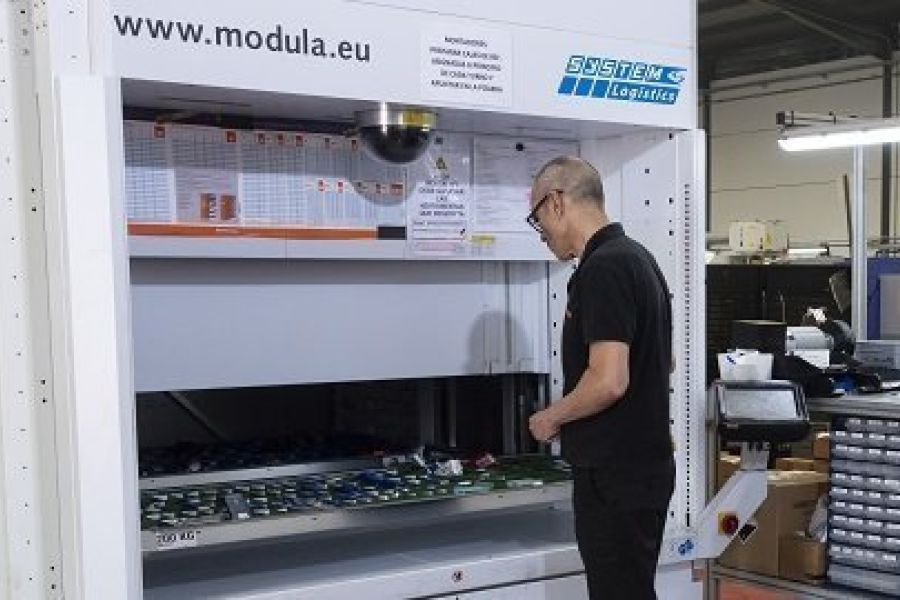

Factor has become the first of the three European sites -alongside Italy and Switzerland- to carry out the final validation phase with real users. This contribution is key for the consortium, which has been able to validate the technology in a 100% real and functional industrial setting, with real processes and equipment in operation.

In this context, operators, technical staff, and prevention trainers have tested the XR platform in real working conditions. Unlike other pilots geared toward medical rehabilitation environments, the validation at Factor has been carried out entirely in a productive environment, involving a team of more than ten professionals.

“For the SUN project, having validations in a real industrial environment is crucial and has allowed us to obtain valuable information about the applicability of XR in the manufacturing sector and its ability to improve safety and efficiency in critical processes”, explained Alfredo Giménez, Director of Innovation.

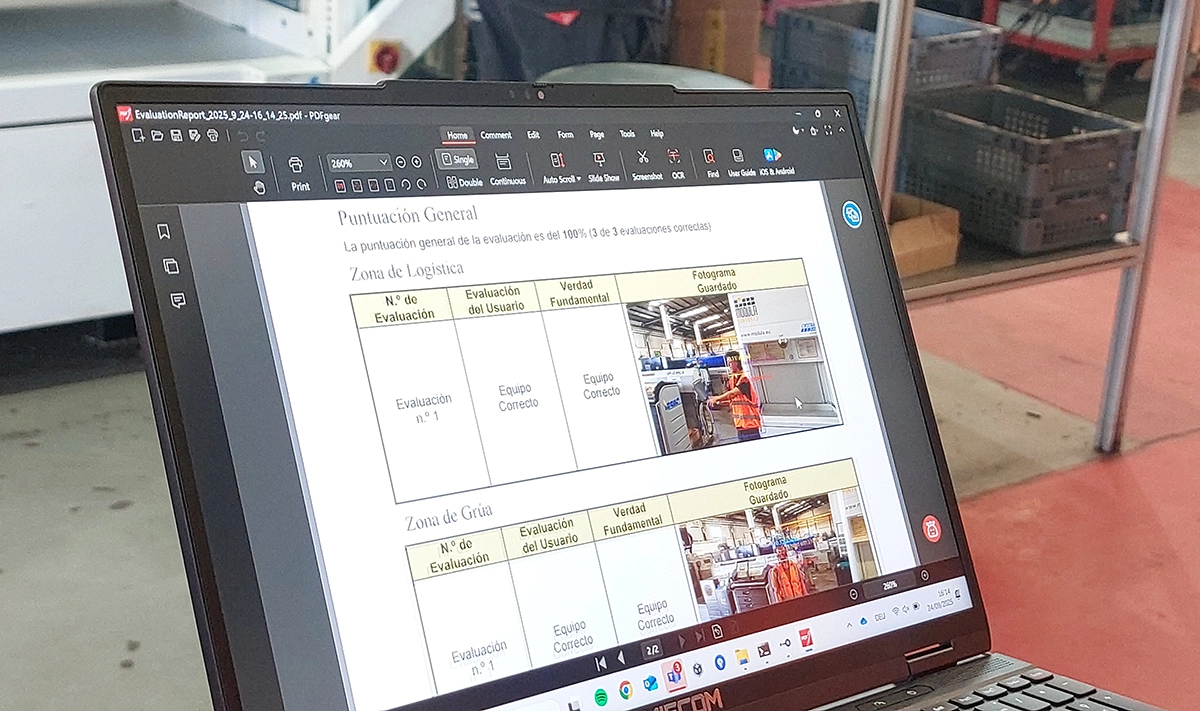

Positive validation results

The assessment of this phase has been very positive. For the Factor team, it has been an opportunity to interact with cutting-edge technologies and see first-hand how they can support their daily work. The participants have been fully involved and their real-time feedback has been essential for the project developers.

The experience has allowed us to observe how technology adapts to the needs of industrial work, becoming more intuitive, useful, and accessible. “It has been a motivating experience for everyone, allowing us to visualize how safety training and industrial safety management will evolve”, said Pablo Rocamora, Head of Innovation Projects.

The transformative potential of XR in industry

Extended Reality has great transformative potential in the short term. Its application allows for:

- Recreating risk simulations without real exposure.

- Improving training in critical situations.

- Facilitate maintenance or assembly tasks through guided remote assistance.

- Reduce the margin for human error.

- Streamline the execution of processes in the plant.

All of this contributes to a safer, more efficient, and more connected work environment, in line with the natural evolution of the sector.

Next steps for the project

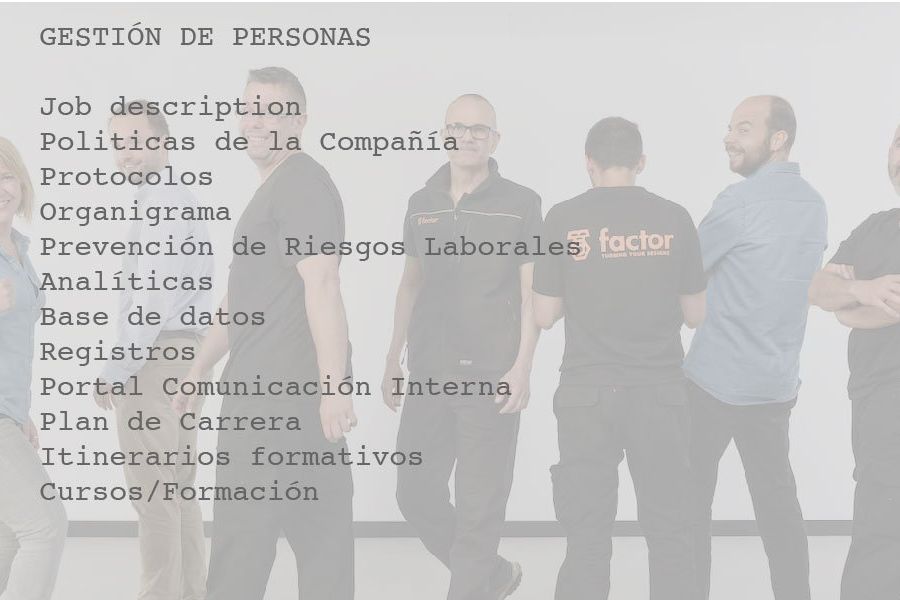

Following validation at our facilities, a detailed analysis of the data and comments collected has been carried out and shared with the other project partners in order to make the final adjustments to the XR platform and ensure that it meets the needs identified.

At the same time, internally, we are analyzing ways to integrate these XR technologies into training programs and safety protocols, thereby reinforcing our commitment to an increasingly safe, advanced, and innovative industrial model.