FACTOR investigates sound patterns to anticipate deviations in machining processes

Research using fiber optics and artificial intelligence makes it possible to detect invisible anomalies, anticipate breakdowns, and optimize maintenance in industrial production environments

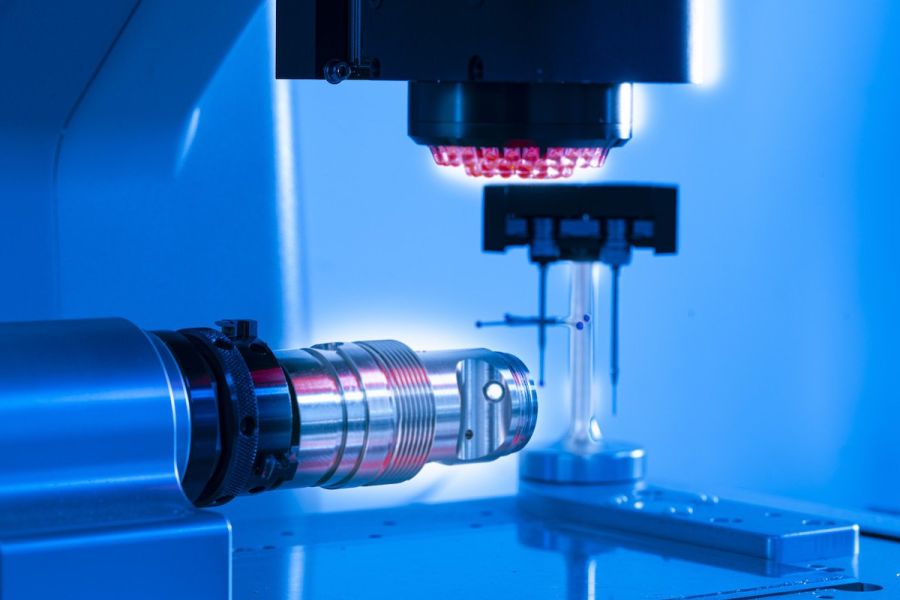

In industrial production environments, where precision and machine availability are critical, Factor has identified the need for tools that can anticipate failures in machining equipment. In many cases, these incidents are not visually apparent, but manifest themselves through vibrations or unusual sounds during machine operation. Detecting these patterns in time prevents minor anomalies from leading to more serious breakdowns.

Anticipate to improve

This need gave rise to the project, which aims to improve the reliability of the production process, reduce the costs associated with corrective maintenance, and provide objective information to facilitate decision-making. To this end, advanced acoustic analysis technologies based on fiber optics and artificial intelligence are being explored in collaboration with specialized technology partners.

The initiative relies on the capture of vibrations and sounds generated by machines during operation using advanced sensors. These acoustic signals are converted into data that an Artificial Intelligence system analyzes to:

- Identify normal process patterns.

- Detect anomalies associated with wear, misalignment, or incipient failures.

- Compare current signals with historical models and anticipate deviations that cannot be detected by traditional methods.

The system acts as an “expert ear”, capable of listening to frequencies that are imperceptible to the operator and detecting abnormal behavior in real time.

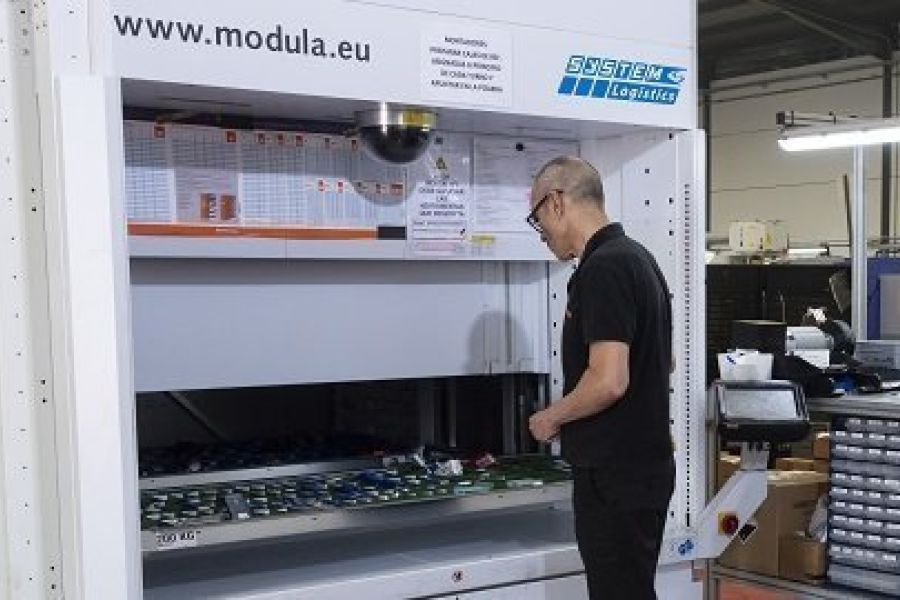

Integration into production

One of the main advantages of this technology is its easy integration into day-to-day production. It is installed in the existing rack without interfering with the normal operation of the machines. While the process runs normally, the sensors collect data that the algorithms process and convert into early warnings when anomalies are detected, providing clear information that helps the production and maintenance team prioritize actions.

Thanks to this approach, it is possible to anticipate tool or bearing wear, detect abnormal vibrations associated with misalignments or misadjustments, reduce unplanned downtime, and improve the availability and service life of the machinery.

Validation and collaboration

The project is being developed at Factor as a real industrial environment, providing the machinery, production context, and process knowledge necessary to validate the technology under production conditions and evaluate its impact in terms of efficiency, maintenance, and process quality.

The collaboration involves the participation of the Instituto Tecnológico de Informática (ITI) and CalSens. On the one hand, the ITI contributes its capabilities in artificial intelligence, signal analysis, and predictive models, interpreting the data captured by the sensors. For its part, CalSens provides fiber optic-based sensor technology, its physical integration, and the infrastructure necessary to capture acoustic signals.

Sound pattern analysis enables more informed operational decisions, such as scheduling maintenance before breakdowns occur, adjusting tools or machining parameters when deviations are detected, identifying the source of defects, or prioritizing interventions based on their criticality and actual evidence. All of this translates into a reduction in unplanned downtime, greater process stability and quality, increased tool and component life, lower maintenance costs, and greater traceability, which contributes to improved decision-making.

From the Innovation Department's perspective, this project is fully aligned with the Smart Manufacturing strategy, as it advances the digitization of the production process, incorporates continuous real-time monitoring, connects maintenance with objective data, and provides tools to improve efficiency, reduce variability, and promote continuous improvement. The initiative thus reinforces the path towards an increasingly connected, predictive, and data-driven factory, in line with the principles of Industry 4.0.